Shape Condition Based Monitoring

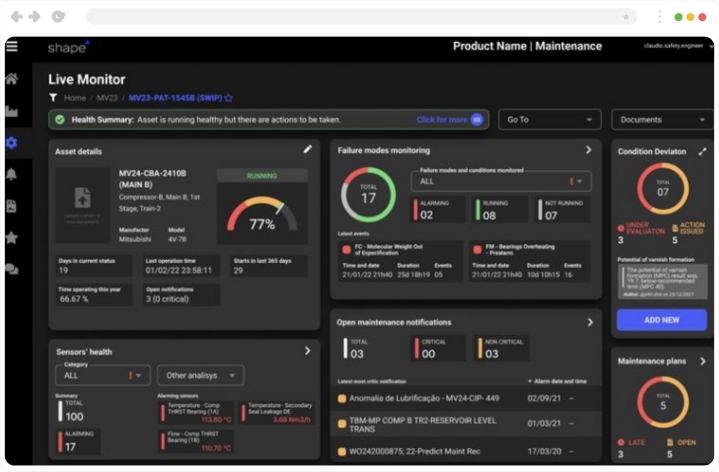

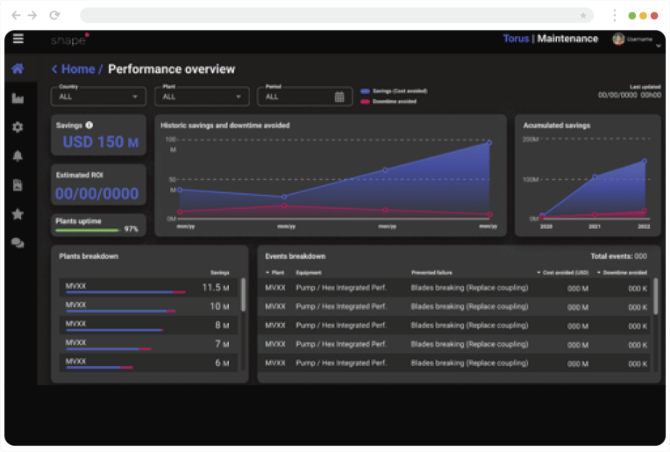

The condition monitoring system is a unique cockpit that integrates all the data needed by the operation and maintenance teams for decision making.

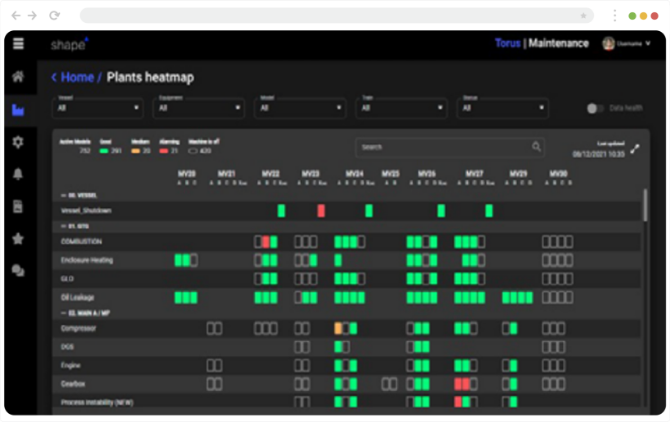

Monitoring ranges from an overview of the plant down to the equipment level. The data monitored by the Condition Monitoring system exclusively considers the systems integrated in the Data Platform and prioritized equipment.

The platform and dashboards are highly customizable according to the available data and the needs of the front teams.

For the implementation of the Condition Monitoring system to be possible:

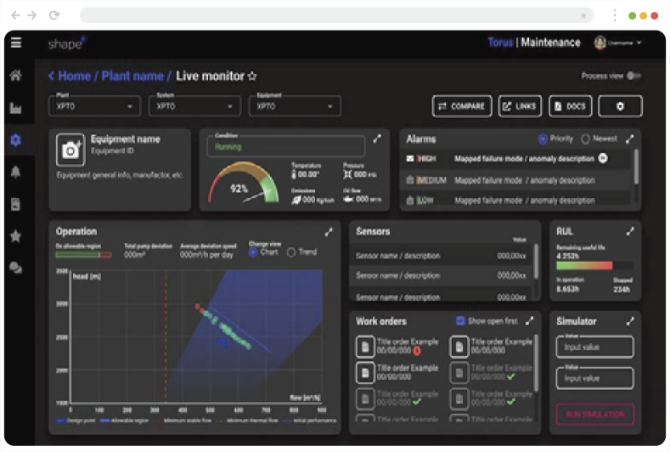

Among the possible integrations of data and visualizations at the device level are:

Condition Based Maintenance (CbM) models aim to alert users when assets are operating out of specification. Higher accuracy but lower reaction time like a PdM tool.

The heat map screen gives managers a bird’s-eye view of the current condition of multiple plants, helping them to allocate resources for diagnosis and treatment.

The alarm manager allows users to quickly identify equipment with a high-risk failure mode and take action to prevent it. Notifications are sent to stakeholders to ensure timely action.

The asset-level dashboard is the one-stop-shop for all information about each asset, including the alarms generated by all predictive and simulation models.

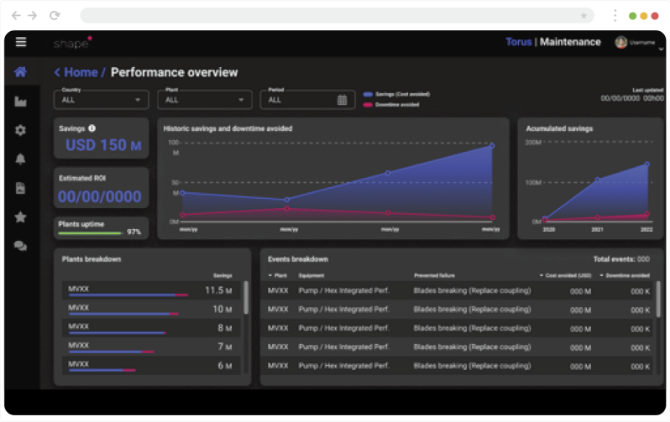

Integrated visualization of the value captured by the solutions in historically avoided downtime. Includes asset performance benchmarking and breakdown of failure events.

WHERE WE ARE

HQ – Rio de Janeiro

Praia do Flamengo, 66

Flamengo, Rio de Janeiro – Brasil

São Paulo

Cubo Itaú – Alameda Vicente Pinzon, 54

Vila Olímpia, São Paulo – Brasil

Singapore

9 North Buona Vista Drive, The Metropolis

Tower 1, #21-01, Singapore 138588